When you choose plastic parts for your plastic products housings, you give your devices a strong shield against the elements. These housings protect sensitive electronics from moisture, dust, impacts, and temperature extremes. The right material and design ensure your products units work reliably, even in harsh environments.

Environmental Resistance

Plastic parts excel at keeping out water and dust. Manufacturers use materials like ABS, PC, and ABS+PC blends to create housings that meet high IP ratings. IP ratings show how well a device resists dust and water. For example, an IP67 means the housing is completely dustproof and can handle immersion in water. This level of protection is essential for GPS devices used outdoors or in industrial settings.

Tip: Always check the IP rating when selecting a GPS housing. An IP67 rating offers full protection against dust and water immersion.We have already provided over 30,000 plastic casing tests for our customers.

| Plastic Type | Typical IP Ratings | Temperature Range (°C) | Impact & Sealing Properties | Application Context |

|---|---|---|---|---|

| ABS | IP65 IP66 IP67 IP68 | -40 to +80 | Good sealing, moderate impact resistance | Outdoor, industrial enclosures requiring dust and moisture protection |

| PC | IP66, IP67 | -40 to +110 | Higher impact resistance, better sealing | Outdoor, industrial, electronic housings with high moisture/dust resistance |

| ABS+PC Blend | IP65, IP66, IP67 | Combined properties | Leverages benefits of both materials | Enhanced durability and protection in GPS tracking housings |

You can see that plastic parts made from these materials provide strong barriers against environmental hazards. Surface treatments such as powder coating, painting, and rubber coating further improve resistance to UV rays, chemicals, These finishes help your GPS devices last longer, even when exposed to rain, mud, or direct sunlight.

Many plastic products housings undergo rigorous field tests. Devices are exposed to high-pressure water jets, dust storms, and extreme temperatures. These tests confirm that plastic parts keep electronics safe and functional in real-world conditions.

Impact Strength

You need GPS housings that can handle drops, bumps, and rough handling. Polycarbonate plastic, a popular choice for GPS enclosures, can withstand This material is about 30 times stronger than acrylic and 250 times stronger than glass. It also has roughly four times the impact resistance of fiberglass. Such strength means your GPS device stays protected if it falls or gets knocked around during transport.

Field tests show that plastic parts perform well in demanding situations. For example, GPS collars for wildlife tracking use,These housings survive bites from animals, rough terrain, and heavy rain. A clear polyester resin coating and rubber gasket seal add extra durability and water resistance. This design keeps the electronics safe, even in the wild.

- Waterproofing: GPS trackers pass tests with high-pressure water jets.

- Impact Resistance: Devices survive drops and collisions in busy supply chains.

- Pressure Resistance: Housings endure of pressure, such as being run over by a forklift.

- Temperature Resistance: Devices operate in extreme cold and heat, protecting battery life and performance.

Plastic parts also resist corrosion, unlike metal housings. This feature is important for GPS devices used in marine, agricultural, or construction environments. With the right material and surface treatment, your GPS housing will stand up to years of use.

Note: Shenzhen zhongyihong(ZEH) Electronic Technology co., ltd in designing and customizing plastic products and molds, combined with high-precision testing, ensures your products housings meet strict durability standards.

Lightweight & Cost

Plastic parts make GPS tracking housings lighter and easier to handle. You can move and install these devices with less effort. Lighter housings also mean lower shipping costs and better portability for field use.

Easy Installation

You benefit from simple designs when you choose plastic enclosures. Most plastic housings use a made with injection molding. This design reduces the number of steps needed for assembly. Workers can put together the parts quickly, which lowers labor costs and shortens installation time. Here are some reasons why installation becomes easier:

- Two-piece plastic housings snap or screw together with minimal tools.

- Simplified assembly means less training for workers.

- Lightweight materials reduce strain during installation.

- Fewer parts and fasteners speed up the process.

| Material Type | Weight Reduction Compared to Metal (Aluminum) |

|---|---|

| Carbon-filled polyphenylene sulfide composite enclosure | Approximately 40% lighter than aluminum enclosures |

| Composite connectors | Traditionally around 40% lighter than metal connectors |

| Optimized composite connectors (with foam introduction) | Additional 10-20% weight savings possible |

You can see that plastic parts housings are than metal alternatives. This weight reduction makes a big difference in both shipping and installation.

Efficient Manufacturing

Injection molding gives you fast, cost-effective production for your plastic housings. The process uses automated machines and multi-cavity molds to produce many parts at once. This lowers the cost per part, especially for large orders. Compared to traditional machining, injection molding offers:

| Injection Molding | Traditional Machining (CNC) | |

|---|---|---|

| Production Volume | High-volume production with multiple-cavity molds enabling many parts per cycle | Generally low-volume, parts made one by one |

| Cost per Part | Lowest price per part at scale due to mold longevity and automation | Higher cost per part, especially for complex or high-volume runs |

| Cycle Time / Speed | Fast cycle times, parts produced rapidly and repeatedly | Slower per part, each machined individually |

| Labor Requirement | Minimal labor beyond setup due to automation | More labor-intensive, requires skilled operators |

| Post-Processing | Minimal post-processing, parts often ready after ejection | Often requires additional finishing or processing |

| Energy Efficiency | Lower energy consumption per part due to fast cycles and automation | Higher energy consumption due to longer machining times |

| Lead Time | due to mold creation but faster production thereafter | Shorter lead time, no tooling required but slower production speed |

| Design Flexibility | Less flexible, limited by mold design and size | More flexible, can handle complex or customized parts |

You save money on both production and shipping when you use plastic parts. The automated process also ensures consistent quality. Our team specializes in designing and customizing plastic products and molds, Shenzhen zhongyihong(ZEH)electronic Technology co.,Ltd using high-precision testing to meet your exact needs.

Plastic Parts Design

You can tailor plastic parts for Plastic housings to match your exact needs.lets you choose slim enclosures with internal cavities and reinforced areas, so you get strength without extra weight. You can select from multiple shapes and sizes, using sketches and rapid prototyping with 3D printing to test ideas quickly. Two-piece units work well for both low-volume CNC machining and mass production with injection molding. The Design for Manufacturing (DFM) stage refines your mold for efficient production.

You can create molds from CAD models in hours, not weeks. This method supports functional testing and design validation before scaling up. PolyJet 3D printing produces silicone molds with fine detail, ideal for complex or thin-walled GPS housings. You benefit from design freedom and cost savings, especially when you need quick iterations.

| size(mm) | Commercial Tolerance (±mm) | Precision Tolerance (±mm) |

|---|---|---|

| 1 to 20 | ±0.075 | ±0.050 |

| 21 to 100 | ±0.150 | ±0.080 |

| 101 to 160 | ±0.305 | ±0.100 |

You can rely on our expertise in designing and customizing plastic products and molds. High-precision testing ensures every part meets your design requirements.

Surface Options

You have many choices for surface finishes, including painting, powder coating, and rubber coating. so you get consistent surfaces without warping or sink marks. Real-time sensors monitor the process, catching defects early. Quality control uses digital inspections, mechanical tests, and visual checks to guarantee smooth finishes and accurate dimensions.

Tip: help maintain cosmetic quality and durability.

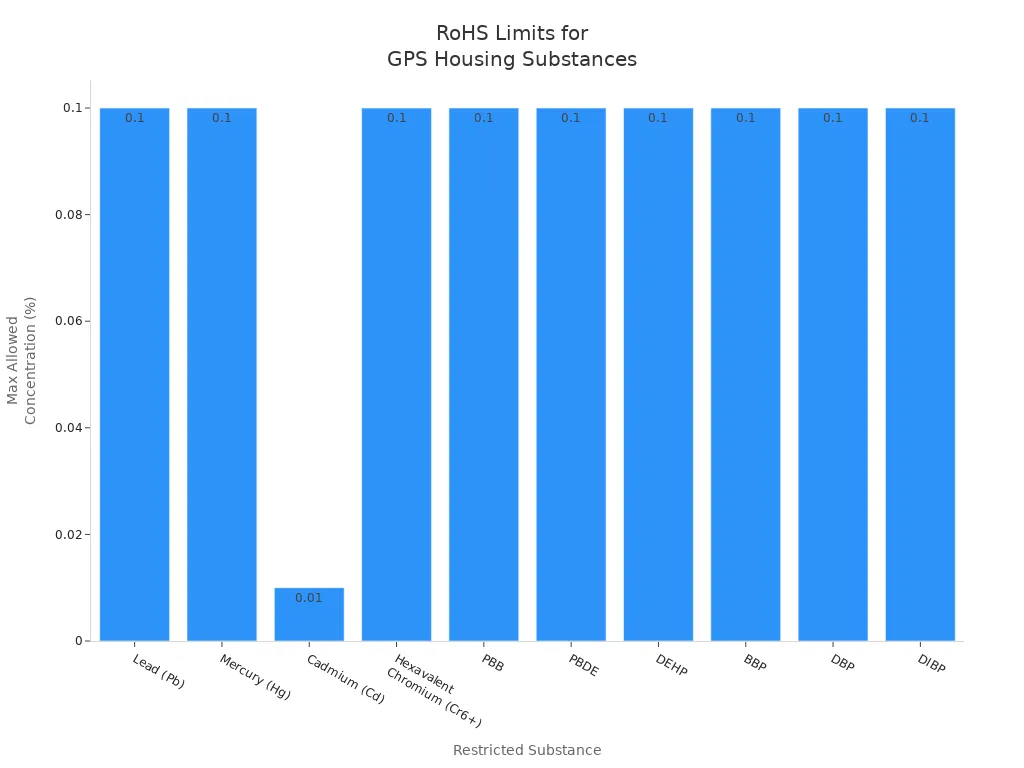

You must meet international standards like RoHS and ISO for your plastic parts housings. such as lead, mercury, and cadmium. You need to use environmentally friendly plastics and lead-free solder. Documentation and certification are required for market access in the EU, USA, and Asia.

protect your plastic box housings during shipping. You can use bubble wrap, packing peanuts, or custom molded inserts to minimize damage and cost. Custom dunnage fits each part, reduces movement, and enhances the unboxing experience.

You gain many advantages by choosing plastic parts for your products housings. These housings offer strong protection, and cost savings. You also enjoy easy customization and fast production cycles.

- ensures precise fit and reliable performance.

Partner with experts in custom plastic design to achieve the best results for your products projects.

FAQ

What materials can you choose for GPS tracking housings?

You can select from ABS, PC, ABS+PC, and many engineering plastics. Each material offers unique benefits for strength, durability, and environmental resistance.

How do you ensure the quality of custom plastic housings?

You benefit from high-precision testing and strict quality control. Our team uses advanced inspection tools to meet your design requirements and deliver reliable products.

Can you customize the design and surface of GPS housings?

Yes! You can request custom shapes, colors, textures, and logo placement. Our experts design and manufacture molds to match your exact needs.

Tip: Share your drawings or ideas with our team for a perfect fit.